#compressor pressure range

Explore tagged Tumblr posts

Text

Aircraft engine types ✈️

✈️Turbo-Shaft: Used in helicopters and some fixed-wing aircraft, it features a compressor, combustion chamber, and turbine. The turbine drives a power shaft via a free (power) turbine, which powers the rotor or propeller through a gearbox, rather than producing direct thrust. Exhaust gases are expelled separately.

✈️Turbo-Prop: Similar to a turbo-shaft, it powers a propeller via a gearbox. Air is compressed, mixed with fuel, and burned in the combustion chamber. The turbine extracts energy to drive the propeller, with some exhaust thrust. It’s efficient for low-speed, short-range flights.

✈️Turbo-Fan: Common in commercial jets, it has a large fan at the front, high- and low-pressure compressors, a combustion chamber, and turbines. The fan accelerates air around the core (bypass air) for thrust, while the core produces additional thrust via exhaust. It’s efficient for high-speed, long-range flights.

✈️Turbo-Jet: An older design, it compresses air, burns fuel in the combustion chamber, and expels exhaust through a nozzle for thrust. It lacks a bypass fan, making it less efficient but capable of high speeds. Used in early jet fighters and some supersonic aircraft.

✈️Ram-Jet: Operates at high speeds (Mach > 1), using forward motion to compress air in the inlet. Fuel is injected and burned in the combustion chamber, and the exhaust is expelled through a nozzle for thrust. It has no moving parts but only works at high speeds.

✈️Scramjet: A supersonic combustion ramjet, designed for hypersonic speeds (Mach > 5). Air enters at supersonic speeds, is compressed, mixed with fuel, and burned in a combustion chamber, with exhaust expelled for thrust. It’s used in experimental hypersonic vehicles.

✈️Rocket: Uses stored propellants (fuel and oxidizer) in a pressure vessel. Propellants are burned in a combustion chamber, and the high-pressure exhaust is expelled through a nozzle for thrust. It operates in space since it doesn’t rely on atmospheric oxygen.

✈️Gas Turbine: Similar to a turbo-shaft, it’s used for power generation or auxiliary power units. Air is compressed, burned with fuel, and the exhaust drives a power turbine, which can power generators or other systems. Bleed valves and discharge ports manage airflow and pressure.

Each engine type is optimized for specific applications, balancing efficiency, speed, and operational environment.

@Airmainengineer via X

805 notes

·

View notes

Text

Top 5 Benefits of Using Rubber Gaskets in Industrial Settings

In the demanding world of industrial manufacturing, efficiency and reliability are non-negotiable. From high-pressure pipelines to sanitary processing systems, one seemingly small component plays a critical role in keeping operations running smoothly: the rubber gasket. At California Rubber, we specialize in precision-engineered rubber gaskets designed for performance, durability, and safety across a wide range of applications.

Rubber gaskets offer significant advantages over metal or fiber alternatives in terms of flexibility, resilience, and resistance to extreme conditions. In this blog, we explore the top five benefits of using rubber gaskets in industrial environments.

1. Superior Sealing Capability

The primary function of any gasket is to create a leak-proof seal between two surfaces, and rubber gaskets excel at this. Thanks to their inherent flexibility and compressibility, rubber gaskets can conform to surface irregularities, ensuring a tight seal even in imperfect or worn flange connections.

This superior sealing capability is particularly vital in high-pressure systems or where liquids and gases must be contained with absolute precision. Components like Sanitary Gaskets used in food and beverage manufacturing rely on high-grade rubber to maintain hygiene and prevent leaks under demanding conditions.

Rubber materials such as EPDM, NBR, and silicone are also excellent at maintaining seal integrity across a wide range of temperatures and pressures, making them ideal for dynamic and static applications alike.

2. Chemical and Temperature Resistance

Industrial environments often expose components to aggressive chemicals and extreme temperatures. Rubber gaskets are available in a variety of formulations that offer excellent resistance to these challenges.

EPDM is commonly used for steam and water applications due to its excellent heat and weather resistance.

Nitrile rubber offers superb resistance to oils, fuels, and other hydrocarbons.

Silicone rubber is ideal for high-temperature sealing up to 230°C (446°F).

This adaptability ensures long-term performance without degradation, reducing the frequency of replacements. It’s particularly valuable in environments such as Cannabis Extraction Parts, where chemical exposure is frequent and operational safety is a top concern.

3. Durability and Longevity

Rubber gaskets are known for their excellent wear and fatigue resistance. When properly installed and maintained, they can provide years of reliable service, even in environments with high levels of vibration, pressure fluctuations, or abrasive materials.

This durability not only lowers the total cost of ownership but also contributes to reduced downtime and maintenance cycles. In sectors like brewing, where production schedules are tight and efficiency is key, using high-performance components such as Brewing Gaskets can significantly improve system reliability.

The use of advanced manufacturing techniques like compression molding and injection molding ensures that rubber gaskets meet precise dimensional tolerances for consistent performance.

4. Noise and Vibration Dampening

In addition to sealing, rubber gaskets offer excellent vibration isolation and noise reduction. Their elastic nature absorbs mechanical energy, dampening vibration between metal parts and reducing wear and fatigue on adjacent components.

This feature is particularly useful in dynamic systems such as pumps, compressors, and HVAC systems. Components like aodd pump parts often integrate rubber seals and diaphragms to ensure quieter operation and longer mechanical life.

By minimizing mechanical noise and vibration, rubber gaskets also contribute to safer and more comfortable working environments in industrial facilities.

5. Versatility Across Applications

Rubber gaskets are incredibly versatile, available in a wide variety of shapes, sizes, and materials to suit almost any industrial requirement. Whether you need a standard flange gasket or a custom-molded seal for a unique configuration, rubber provides a flexible solution.

Their usage spans industries including:

Food and beverage processing

Pharmaceuticals and biotechnology

Oil and gas

Automotive and aerospace

Water treatment and chemical processing

Rubber gaskets can also be tailored to meet regulatory and compliance standards such as FDA, NSF, and USP Class VI, depending on the application.

From standard sealing tasks to highly specialized roles, rubber gaskets can be engineered to solve complex challenges efficiently and economically.

Maintenance Tips for Longer Gasket Life

To get the most out of rubber gaskets, consider these simple but effective maintenance tips:

Perform regular visual inspections for signs of wear, cracking, or hardening.

Ensure proper torque is applied during installation to avoid over-compression.

Store spare gaskets in a cool, dry place away from sunlight and ozone sources.

Replace gaskets at the first sign of leakage to prevent downstream damage.

Proactive care will maximize the life span of your gaskets and ensure uninterrupted system performance.

Why Rubber Gaskets Are a Smart Investment

Rubber gaskets are not only a practical solution for sealing and insulation but also a strategic choice for improving operational efficiency. With the right material and design, they reduce maintenance needs, enhance equipment life, and support safe, clean processing environments.

For manufacturers in regulated industries, choosing the correct gasket material is also key to maintaining product quality and compliance. Investing in high-performance rubber gaskets is ultimately an investment in your operation’s reliability and success.

Conclusion

Rubber gaskets offer a powerful combination of sealing performance, chemical resistance, durability, and versatility that make them indispensable in modern industrial settings. At California Rubber, we understand the critical role gaskets play in your operations, and we offer expertly engineered solutions to meet the most demanding requirements.

Whether you're upgrading aodd pump parts, installing FDA-compliant seals in food processing systems, or customizing Brewing Gaskets for specialized production needs, we provide the quality and expertise you can rely on. Reach out today to learn how our custom rubber gasket solutions can optimize your systems and extend the life of your equipment.

2 notes

·

View notes

Text

Nice to meet you all! My name is Ash, I'm nearly 25, and I'm an artisan dicemaker! I'm nonbinary and use they/them pronouns. Below are some examples of my signature D20, hand designed by me!

I'm hoping to post actively on here. Excited to meet everyone! I'm always willing to answer questions about the dicemaking process, so feel free to pop me an ask! For now, here's some FAQ's and samples of my work!

Q: How long have you been making dice?

A: I've been making dice for about 2 years now! I began resin crafting 5 years ago, and only felt confident in my ability to start dicemaking after 3 years of intense research and practice!

Q: How do you determine your pricing?

A: My dice are priced based on a number of factors. My equipment such as the resin, pressure pot, air compressor, and all additives (think glitter, resin dye, etc.) are not cheap! Neither is my time & expertise. Currently my sets range in price from $60 to $120 depending on a number of factors including complexity and rush time. I do occasionally run sales! My single D20's also range in price depending on complexity from $20 to $100.

While I understand having a budget (I am willing to work with you!) I ask that all price inquiries be respectful of my time and expertise.

Q: Are your dice balanced?

A: Short Answer: Yes! Long Answer: Yeeeeeees. Just kidding! My dice are made using a pressure pot that eliminates bubbles in the resin. They are as balanced as they come!

Q: Do you accept commissions/are your commissions open?

A: Check my bio! I will say if my commissions are open there. If you're unsure, feel free to pop me a message, but please understand it may take me a moment to get to you!

Q: Are you a fan of xyz D&D show/podcast?

A: Probably! Admittedly I don't have time to listen or watch as many as I'd like. But I've dabbled in Dimension 20, Critical Role, and Dungeons & Daddies to name a few!

Q: What class do you play in DnD?

A: I am usually a Cleric or a Druid! But always and forever a Goblin Rights Advocate. If you are an artist, I may be down to art trade dice for a portrait of my OC's!

Q: What are some examples of your work?

Thanks for reading, and have a wonderful day!

25 notes

·

View notes

Text

DUBAI, United Arab Emirates (AP) — Yemen's Houthi rebels likely fired an Iranian-made anti-ship cruise missile at a Norwegian-flagged tanker in the Red Sea in December, an assault that now provides a public, evidence-based link between the ongoing rebel campaign against shipping and Tehran, the U.S. military says.

A report by the U.S. Defense Intelligence Agency released Wednesday linked the attack on the Strinda, which set the vessel ablaze, to Tehran, the Houthi's main backer in Yemen's nearly decadelong war. The findings correspond with those of a Norway-based insurers group that also examined debris found on the Strinda.

It comes as the Houthis continue their monthslong campaign of attacks over the Israel-Hamas war, targeting ships in the Red Sea corridor, disrupting the $1 trillion flow of goods passing through it annually while also sparking the most intense combat the U.S. Navy has seen since World War II.

Iran's mission to the United Nations, responding to questions from The Associated Press, again denied arming the Houthis despite the reports.

“We are aware that (the Houthis) have significantly developed their military capabilities relying on their very own sources,” the mission said. "The prolonged war against them is the primary factor behind the expansion of their military prowess.”

The Strinda was coming from Malaysia and was bound for the Suez Canal and then on to Italy with a cargo of palm oil when it was struck by a missile Dec. 11. The attack sparked a major fire on board that the crew later extinguished without anyone being hurt.

Debris found on board later was analyzed by the U.S. military. The DIA compared the pieces of the engine from the missile found on board to the Iranian Noor anti-ship ballistic cruise missile.

“The Iranian Tolu-4 turbojet engine, used in the Noor (missile), has unique features — including the compressor stage and stator — that are consistent with engine debris recovered from the ... Houthi attack on the M/T Strinda,” the DIA report said. A stator is the stationary portion of an engine.

Those pieces match images of a Tolu-4 engine that Iran displayed at the International Air and Space Show in Russia in 2017, the DIA said. Visually, the engines bore similarities in the photographs.

The Noor was reverse engineered by Iran from the Chinese C-802 anti-ship missile, which Iran purchased from Beijing and began testing in 1996 before transfers stopped over a U.S. pressure campaign. The Iranian version is believed to have a range of up to 170 kilometers (105 miles), with an upgraded version called the Qader having a range up to 300 kilometers (185 miles). The Houthis have a look-alike missile to the Qader called the Al-Mandeb 2 with a similar range.

The Norwegian Shipowners’ Mutual War Risks Insurance Association, known by the acronym DNK, also examined the debris following the Strinda attack. The association assessed it was “highly likely” the vessel had been hit by a C-802 or Noor anti-ship cruise missile.

Before the Houthis swept into Yemen's capital, Sanaa, in 2014, the country did not have an arsenal of C-802 missiles. As the Saudi-led coalition entered Yemen’s conflict on behalf of its exiled government in 2015, the Houthis’ arsenal was increasingly targeted. Soon — and despite Yemen having no indigenous missile manufacturing infrastructure — newer missiles made their way into rebel hands.

Iran long has denied arming the Houthis, likely because of a yearslong United Nations arms embargo on the rebels. However, the U.S. and its allies have seized multiple arms shipments bound for the rebels in Mideast waters. Weapons experts as well have tied Houthi arms seized on the battlefield back to Iran.

While the U.S. has previously accused Iran of supplying the missiles the Houthis use in their attacks at sea, Wednesday's report provided photographic evidence for the first time. The report pointed to a seizure stemming from a Jan. 11 nighttime raid of an Iranian dhow traveling near the coast of Somalia, which saw two Navy SEALs killed. The Navy seized parts related to the Noor anti-ship cruise missile, the report said.

The Houthis have launched seaborne attacks since 2016, when they hit the Emirati vessel SWIFT-1 with a missile as it sailed back and forth in the Red Sea between an Emirati troop base in Eritrea and Yemen. They also tried to attack the USS Mason, an Arleigh Burke-class guided missile destroyer, around the same time.

But the Houthi attacks have rapidly escalated since November over the Israel-Hamas war in the Gaza Strip. The rebels have targeted more than 70 vessels by firing missiles and drones in their campaign that has killed four sailors. They have seized one vessel and sank two in the time since.

The Houthis maintain that their attacks target ships linked to Israel, the United States or Britain as part of the rebels’ support for the militant group Hamas in its war against Israel. However, many of the ships attacked have little or no connection to the war — including some bound for Iran, which backs the Houthis.

“The Houthis probably have used Iran-supplied weapons to conduct more than 100 attacks against land-based targets in Israel, Saudi Arabia, the United Arab Emirates, and Yemen and dozens of attacks targeting ships in the Red Sea and Gulf of Aden,” the DIA report said.

Meanwhile early Friday, the private security firm Ambrey reported that a ship traveling in the southern Red Sea saw what appeared to be a missile splash into the sea and another explode in the air nearby.

The U.S. military's Central Command meanwhile reported that it destroyed five Houthi drone boats and two airborne drones in the Red Sea, while destroying another drone in Houthi-controlled territory.

The Houthis did not immediately acknowledge either incident, though it said U.S.-led airstrikes had targeted the Hodeida region Thursday.

10 notes

·

View notes

Text

Primary investigation on ram-rotor detonation engine

Detonation is a supersonic combustion wave, characterized by a shock wave driven by the energy release from closely coupled chemical reactions. It is a typical form of pressure gain combustion, converting chemical energy into thrust efficiently. The concept of harnessing detonation to improve thermodynamic cycle efficiency and enhance the performance of aerospace propulsion systems has been a subject of interest for many years. Since the 1950s, various types of detonation engines have been proposed, including pulse detonation engines, oblique detonation engines, and rotating detonation engines. However, these three types of detonation engines encounter challenges such as poor thrust continuity, high starting Mach numbers, and insufficient performance gains, which limit the widespread application of detonation propulsion technology.

In a recent article featured in the Chinese Journal of Aeronautics, Dr. Haocheng Wen and Prof. Bing Wang from Tsinghua University proposed a new concept for detonative propulsion, called the Ram-Rotor Detonation Engine, which is expected to break through the limitations of the above-mentioned detonation engines.

“The original intention of developing this new engine is to improve the structures of rotating detonation engines,” said Dr. Haocheng Wen, “this concept is also inspired by the ram-rotor compressor.” The ram-rotor detonation engine, abbreviated as RRDE, mainly consists of a rotating rotor with blades, and a stationary casing. The blades on the rotor are distributed in a helical symmetric manner. The combustible mixture undergoes compression, detonation combustion, and expansion within the variable cross-sectional channels between the blades.

The authors performed primary theoretical and numerical investigation on the RRDE. They established a theoretical model to analyze the relationship between the propulsion performance and parameters such as inlet velocity, rotor rim velocity, and equivalence ratio. It is indicated that for the stoichiometric hydrogen/air mixture, the total pressure gain of RRDE can exceed 3. Furthermore, they also conducted numerical simulations on the typical structure of RRDE and obtained the characteristic flow field and propulsion performance of engine. Their simulation results demonstrate that the detonation wave can stabilize and remain stationary within the blades by the given configuration, and can adapt to the variations in parameters such as the equivalence ratio within a certain range. “Our study primarily verifies the performance benefits and operation feasibility of the RRDE.” said Dr. Haocheng Wen.

The authors believe that the RRDE has several advantages, including a simple and compact structure, high efficiency, and the adaptability to a wide-range of flight Mach number. However, they also candidly acknowledge that the realization of the RRDE is confronted with numerous challenges that demand resolution, such as the stabilization mechanism of detonation wave, supersonic boundary layer interference, implementation of high-speed rotor, as well as thermal protection, etc. “Our team is conducting ongoing research on key scientific and engineering issues in RRDE.” said Prof. Bing Wang. They expect the RRDE can provide high-performance propulsion for the supersonic vehicles in the future.

IMAGE: Conceptual scheme of a supersonic vehicle using the ram-rotor detonation engine Credit Chinese Journal of Aeronautics

4 notes

·

View notes

Text

Genergy is a Spanish brand founded in 2008, with headquarters located in Calahorra, La Rioja. From our beginnings we are specialized in manufacturing of portable electric generators and all kind of machinery powered by heat engines.

Genergy Power Products distributes its products in different markets, specially Europe under the brands Genergy, MGA-Spain and Zero Emission. Three prestigious brands, recognized in national and international markets, and that offer solutions to any isolated energy needs. MGA is specialized in portable generators with gasoline engines and digital inverter generators, especially suitable for domestic uses or hobby. Under Genergy brand we manufacture gasoline electric generators, 1500 RPM diesel generators and a complete range of professional machinery as air compressors, welder generators, high pressure washers, water pump, portable power stationp, etc. And finally, Zero Emission offers energy solutions more sustainable and respectful with the environment. Products that significantly reduce consumption and harmful emissions, and allow us to manage our energy more intelligently.

1 note

·

View note

Text

Drilling Air Compressors: Everything You Need to Know

What are drilling air compressors?

Drilling air compressors are used to power a variety of drilling tools, including pneumatic drills, impact wrenches, and air hammers. They are essential for a variety of construction and industrial applications, including:

Foundation work

Concrete work

Masonry work

Plumbing work

Mechanical workHow do drilling air compressors work?

Drilling air compressors work by compressing air and storing it in a tank. The compressed air is then released to power the drilling tools. The pressure of the compressed air is measured in pounds per square inch (PSI).

Types of drilling air compressors

There are two main types of drilling air compressors:

Electric air compressors are powered by electricity. They are the most common type of drilling air compressors and are typically used for light-duty applications.

Diesel air compressors are powered by diesel fuel. They are more powerful than electric air compressors and are typically used for heavy-duty applications.

Factors to consider when choosing a drilling air compressor

When choosing a drilling air compressor, it is important to consider the following factors:

Air flow: The air flow is the amount of air that the compressor can deliver. The higher the air flow, the more powerful the compressor.

Pressure: The pressure is the force of the compressed air. The higher the pressure, the more powerful the drilling tools can be.

Tank size: The tank size determines how long the compressor can run without having to be refilled.

Noise level: Drilling air compressors can be noisy. Choose a compressor with a low noise level if you will be using it in a residential area.

Price: Drilling air compressors can range in price from a few hundred dollars to several thousand dollars. Choose a compressor that fits your budget.

Safety tips for using drilling air compressors

Here are some tips for using a drilling air compressor safely:

Always wear safety glasses when using a drilling air compressor.

Do not overload the compressor.

Keep the compressor clean and free of debris.

Follow the manufacturer's instructions.

Conclusion

Drilling air compressors are a versatile tool that can be used for a variety of tasks. By understanding the different types of drilling air compressors and the factors to consider when choosing one, you can be sure to choose the right compressor for your needs.

2 notes

·

View notes

Text

Application Of Tewatt Mobile Air Compressors In Water Wells And Geothermal Projects

Tewatt mobile air compressors, equipped with the world's leading heavy-duty VOLVO diesel engine, international top-tier dedicated electric motors for compressors, exceptional American Tewatt screw compressor host, an oversized military-grade radiator, a stable and straightforward control system, and a heavy-duty filtration system among other premium components. These specifications make Tewatt's mobile air compressors apt for the harsh conditions encountered in water wells and geothermal projects, making them extensively used in such constructions.

Requirements and Characteristics of Water Wells and Geothermal Projects:

The industry usually employs diesel mobile compressors for water wells and geothermal projects, demanding high exhaust volume, high pressure, and frequent mobility. Depending on the project, the requirements for compressors differ between water and geothermal wells. Since geothermal wells generally have a much deeper drilling depth than water wells, they often adopt multiple parallel machines.

Working conditions: Construction is more common in the colder northern parts of China, with some areas being at a higher altitude.

The typical compressor exhaust volume ranges from 21m3/min to 35m3/min, and the exhaust pressure is between 18kg/cm2 and 35kg/cm2. The drilling diameter ranges from 100mm-400mm.

Air drilling efficiency is significantly higher than the traditional water drilling method and is the inevitable trend for the drilling industry's future development.

Solutions:

Addressing the water well and geothermal industry's needs, our company has specifically developed a high-pressure compressor with an exhaust pressure of 25kg/cm2 and an exhaust volume of 31.5m3/min. With our drilling equipment, we can easily penetrate a 300mm diameter and 200m deep granite geological structure. If two 25kg/cm2, 30m3/min compressors are paired with a 100kg/cm2 booster, we can achieve up to 2800m for geothermal projects, marking a pioneering achievement with our partners.

Given the frequent mobility required by water wells and geothermal projects, we've designed a vehicular high-pressure compressor for easy relocation, eliminating the need for separate power drives, lifting, or transportation, saving users significant time and cost. It's exceptionally convenient for operations within a 100km range.

Our large exhaust volume, dual-stage high-pressure screw compressor, meets the needs of users requiring even higher pressures.

In terms of drilling and geothermal projects, our products have gained widespread recognition in places like Xinjiang, Shandong, Northeast, Henan, and Yunnan. Notably, in Yunnan's Qujing voluntary drought-resistance project, we completed our mission successfully, receiving attention from local television stations and government interviews.

We can provide all drilling clients with a set of efficient, advanced solutions and equipment plans based on their requirements. We also offer a comprehensive cost and maintenance plan for the entire equipment set, addressing professional air drilling issues.

Tewatt mobile air compressors boast reliability, stability, energy efficiency, and environmental friendliness. They are also resilient to extreme conditions, such as high temperatures, severe cold, high dust, and high altitudes, maintaining exemplary performance in harsh environments. The intelligent control system further ensures equipment stability and simplifies operations. Tewatt compressors undoubtedly have a promising application future in water wells and geothermal projects.

2 notes

·

View notes

Text

Maintenance Tips to Keep Your VRF Air Conditioning System Running Smoothly

VRF (Variable Refrigerant Flow) air conditioning systems have become a popular choice for modern buildings due to their energy efficiency, zoning flexibility, and quiet operation. Whether installed in high-end residences, commercial offices, hotels, or healthcare facilities, VRF systems offer intelligent temperature control and long-term cost savings.

However, like all HVAC systems, VRF units require regular maintenance to operate at peak performance. Neglecting service schedules can lead to decreased efficiency, higher energy bills, and costly repairs. Fortunately, with proper care, a VRF system can run smoothly for many years.

Here are some essential maintenance tips to keep your VRF air conditioning system in top shape.

1. Clean or Replace Air Filters Regularly

One of the simplest yet most important maintenance tasks is cleaning or replacing the indoor unit’s air filters. Dust, pollen, and pollutants accumulate on filters over time, obstructing airflow and reducing cooling efficiency.

Frequency: Check filters every 30 to 60 days.

Tip: For dusty environments or commercial spaces, inspect them more frequently.

Dirty filters not only reduce efficiency but also strain the system, causing the compressor to work harder, which can reduce its lifespan.

2. Inspect and Clean Outdoor Units

VRF systems have outdoor condenser units that should be kept clean and unobstructed to ensure proper heat exchange.

Clear debris, leaves, or obstructions from around the unit.

Use a soft brush or low-pressure water to clean the coil fins gently.

Ensure there’s at least 2–3 feet of clearance around the unit for airflow.

Blocked outdoor units can lead to overheating, poor performance, and eventual system failure.

3. Check Refrigerant Levels and Line Integrity

VRF systems depend on precise refrigerant levels for optimal performance. Leaks or low refrigerant levels can disrupt the system’s cooling capacity and energy efficiency.

Schedule professional refrigerant checks annually.

Inspect the refrigerant lines for signs of oil stains, which may indicate a leak.

Monitor for unusual cooling behavior like inconsistent temperatures or high indoor humidity.

Refrigerant leaks can be harmful to both the environment and your system’s components if left unchecked.

4. Ensure Proper Software and Control Calibration

Most modern VRF systems are equipped with advanced controllers and smart zoning capabilities. Over time, these settings may require recalibration.

Check that zone temperatures are accurately set and functioning.

Ensure that scheduling features and energy-saving modes are correctly configured.

Update the firmware/software if new versions are available from the manufacturer.

Well-calibrated controls enhance both comfort and energy savings.

5. Schedule Annual Professional Maintenance

While DIY tasks like cleaning filters are essential, a comprehensive annual maintenance check by a certified HVAC technician is crucial.

A typical service should include:

Indoor and outdoor coil cleaning.

Drain line and pan cleaning to prevent mold or blockages.

Electrical connection inspections.

Compressor and fan motor performance testing.

System diagnostic using manufacturer tools/software.

Preventive maintenance helps identify minor issues before they escalate into costly repairs.

6. Monitor Noise and Vibration Levels

One of the advantages of VRF systems is their quiet operation. If you start to hear buzzing, grinding, or unusual vibrations, it may indicate a mechanical issue.

Inspect fan blades for dirt buildup or misalignment.

Ensure units are securely mounted.

Contact a technician if noises persist—early intervention can prevent serious mechanical failure.

Conclusion

A well-maintained VRF air conditioning system delivers superior comfort, efficient cooling, and long-term reliability. By following these maintenance tips—ranging from simple filter checks to professional servicing—you can keep your system running smoothly and maximize your investment.

Whether your VRF system cools a luxury villa or a multi-floor office complex, regular maintenance ensures it continues to deliver quiet, precise, and energy-efficient climate control year-round.

0 notes

Text

The Blackbird crew who flew 15,000 miles, in 10 hours 30 minutes non-stop to see how many times the SR-71 could refuel before the liquid nitrogen gave out

J58 engine

SR-71 liquid nitrogen

Five aerial refuellings

SR-71 liquid nitrogen Dewar’s

J58 engine

The SR-71, unofficially known as the “Blackbird,” was a long-range, advanced, strategic reconnaissance aircraft. Throughout its nearly 24-year career, the SR-71 remained the world’s fastest and highest-flying operational aircraft. From 80,000 feet, it could survey 100,000 square miles of Earth’s surface per hour.

The SR-71 aircraft (like its forerunners, the Lockheed A-12 and YF-12A prototype interceptor) is powered by two 34,000 lbf (151,240 N) thrust-class J58 afterburning turbojet engines.

The J58 engine was developed in the late 1950s by Pratt & Whitney Aircraft Division of United Aircraft Corp. to meet a US Navy requirement. It was designed to operate at speeds of Mach 3+ and at altitudes of more than 80,000 feet. The J58 was the first engine designed to operate for extended periods using its afterburner, and it was the first engine to be flight-qualified at Mach 3 for the US Air Force (USAF).

CLICK HERE to see The Aviation Geek Club contributor Linda Sheffield’s T-shirt designs! Linda has a personal relationship with the SR-71 because her father Butch Sheffield flew the Blackbird from test flight in 1965 until 1973. Butch’s Granddaughter’s Lisa Burroughs and Susan Miller are graphic designers. They designed most of the merchandise that is for sale on Threadless. A percentage of the profits go to Flight Test Museum at Edwards Air Force Base. This nonprofit charity is personal to the Sheffield family because they are raising money to house SR-71, #955. This was the first Blackbird that Butch Sheffield flew on Oct. 4, 1965.

SR-71 liquid nitrogen

An engineering marvel, the J58 had a single-shaft rotor design with a novel compressor bleed bypass when in extreme high-speed operation. What made this engine so unique is the six bypass tubes, which directed airflow from the compressor stage directly into the afterburner. This allowed the Blackbird to operate at a much higher fuel efficiency than other afterburning jet engines when in full afterburner (AB).

On Apr. 26, 1971, pilot Lt. Col. Thomas Estes and RSO Lt. Col. Dewain Vick (he and his family were one of my neighbors at Beale AFB) flew SR-71 #968 15,000 miles in 10 hours 30 minutes non-stop on a grueling marathon mission to test the endurance of the J58 engines and the Blackbird airframe, but mostly to see how many times they could refuel before the liquid nitrogen gave out. At Blackbird speeds and temperatures, oxygen becomes explosive and can spontaneously ignite in the tanks and fuel lines. In order to prevent this, all 6 fuel tanks are purged with pure nitrogen before being filled.

The Blackbird also carries 260 liters of liquid nitrogen in 3 dewars [for this flight the SR-71 only had 2 – 106 liter liquid nitrogen dewars. The 3rd 50 liter dewar was added in the mid 1980’s]. This nitrogen expands into its gaseous form as it is pumped into the fuel tanks to top them off as fuel is consumed. Without the nitrogen, the empty fuel tanks would cavitate from the increased pressure when returning to lower altitudes to refuel.*

Five aerial refuellings

Taking off from Beale AFB in California, they flew 2 laps around the continental United States via Missoula, Montana; east to Bismark, ND; southeast to Peoria, IL; east to Columbus, OH; southeast to Cape Hatteras, NC; southwest to Gainsville, FL; south to Tampa, FL; west to San Antonio, TX; northwest to El Paso, TX; west to El Centro, CA; then back to Beale AFB. Once the second lap was complete, they entered the third lap and turned south at Bismark, for Santa Fe, NM; then west to Las Vegas, NV; then finally back to Beale (flight plan via Ron Kloetzli). This 15,000 mile, 10.5 hour flight required five aerial refuellings. After the flight the aircraft was thoroughly examined and found to be none the worse for the experience. The SR-71 remains to this day the only aircraft rated to run in full continuous afterburner.

I interviewed Colonel Shelton about his 13-hour flight during the Yom Kippur war. And he said that after a long flight like this his adrenaline was hyped up so high that he was unable to sleep even though he was exhausted.

To help with his adrenaline being on overdrive he would go for a long walk to settle down.

This print is available in multiple sizes from AircraftProfilePrints.com – CLICK HERE TO GET YOURS. Dawn at 80.000ft – SR-71 Blackbird

SR-71 liquid nitrogen Dewar’s

On Sep. 20, 1971, Estes and Vick were awarded the 1972 Harmon International Trophy by President Richard Nixon for their accomplishment. They were also awarded the 1971 Mackay Trophy for the same flight.

*Crew Chief Floyd Jones explains: ‘The SR-71 does have three LN2 Dewar’s, two in nose wheel and the third in the left chine are just outboard of K bay. The LN2 goes from the Dewar’s to coils (heat exchange) in tanks 1 and 3 that turns the Liquid into gasses of nitrogen. The wing tanks are the ones that have the worse leaks. Reason being that during the in-flight refueling tanks 3 & 6 are empty during the refueling the excess Hot tanks and the very Cold Fuel cause the Tank Sealant to fracture (crack) causing leaks.’

Be sure to check out Linda Sheffield Miller (Col Richard (Butch) Sheffield’s daughter, Col. Sheffield was an SR-71 Reconnaissance Systems Officer) Twitter X Page Habubrats SR-71, Instagram Page SR71Habubrats and Facebook Page Born into the Wilde Blue Yonder Habubrats for awesome Blackbird’s photos and stories.

Source www.Habu.org

@Habubrats71 via X

#sr 71#sr71#sr 71 blackbird#blackbird#aircraft#usaf#lockheed aviation#skunkworks#aviation#mach3+#habu#reconnaissance#cold war aircraft

67 notes

·

View notes

Text

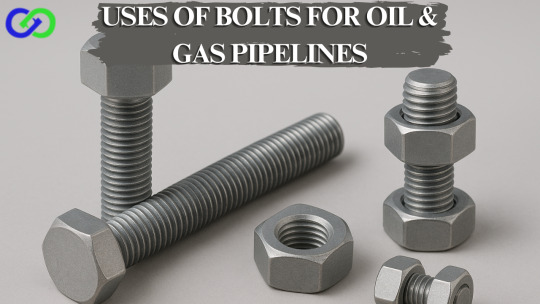

Uses of Bolts for Oil & Gas Pipelines

Introduction

In the oil and gas industry, pipelines serve as the lifelines for transporting crude oil, natural gas, and refined products over long distances. These critical infrastructures demand components that ensure safety, durability, and performance under extreme conditions. Bolts, though small in size, play a vital role in the assembly, integrity, and maintenance of oil & gas pipeline systems.

This blog delves into the importance, various types, and specific applications of bolts in oil and gas pipeline systems.

Importance of Bolts in Oil & Gas Pipelines

Bolts are critical mechanical fasteners that securely connect two or more components. In oil and gas pipeline systems, they serve to:

Secure flange connections

Support valve assemblies

Withstand high pressure and temperature

Resist corrosion from harsh chemicals and environmental conditions

Enable easy maintenance and disassembly

Any failure in bolted joints could result in leaks, production downtime, or safety hazards, making bolt selection and installation critical to pipeline integrity.

Key Applications of Bolts in Oil & Gas Pipelines

1. Flanged Connections

Used to bolt two pipe ends together using gaskets.

Ensure tight sealing in high-pressure, high-temperature environments.

They typically use high-strength stud bolts and nuts in accordance with ASME B16.5 or B16.47 standards.

2. Valve Installation

Bolts attach valves to pipelines, allowing for effective regulation of flow and pressure within the system.

They must withstand frequent operation and significant mechanical stress.

3. Compressor & Pump Stations

They anchor rotating machinery like pumps and compressors to the pipeline system, ensuring stable and reliable operation.

Require vibration-resistant bolts with high tensile strength.

4. Manifolds & Headers

Bolts connect complex pipe networks for distributing or collecting fluids.

Used in both upstream and downstream systems.

5. Pipeline Supports and Anchors

Anchor bolts fix supports that carry the pipeline’s weight and thermal expansion.

Must withstand static and dynamic loads.

Types of Bolts Used in Oil & Gas Pipelines

Stud Bolts

Common in flange connections; used with two nuts

Hex Head Bolts

Used in areas requiring easy access for tightening

Anchor Bolts

Secure pipelines and equipment to concrete foundations

U-Bolts

Support pipes in hangers or saddle mounts

Heavy Hex Bolts

Provide additional contact surface for high-load applications

Material Considerations for Oil & Gas Pipeline Bolts

Pipelines are often exposed to corrosive environments, including:

Sour gas (H₂S presence)

Saline offshore environments

High-temperature fluids

Acids and hydrocarbons

Common Materials Used:

Carbon Steel (B7)

High tensile strength; cost-effective; used in non-corrosive environments

Stainless Steel (316, 304)

Good corrosion resistance; suitable for moderate environments

Duplex / Super Duplex

Excellent corrosion resistance and strength; ideal for offshore use

Inconel / Monel / Hastelloy

For extreme conditions involving acids, heat, or seawater

PTFE or Xylan Coated Bolts

Enhanced resistance against galling and corrosion

Industry Standards for Pipeline Bolts

Bolts used in oil & gas pipelines must meet stringent international standards, such as:

ASTM A193 / A194 – For high-temperature and pressure service

ASME B16.5 / B16.47 – Flange dimensions and bolting

API Standards – For pipeline construction and pressure testing

Conclusion

Though often overlooked, bolts are critical components in the oil and gas pipeline infrastructure. Their correct selection, installation, and maintenance ensure the safety, reliability, and longevity of pipeline systems in some of the world’s harshest environments. From securing flange joints to supporting heavy equipment, bolts must be engineered to withstand extreme mechanical and chemical stresses.

Ananka Group offers a wide range of high-performance bolts that meet the demanding specifications of the oil and gas industry. With precision manufacturing, premium materials, and adherence to international standards, our fasteners are trusted in pipeline projects around the world.

FAQ

Q1: What are the different types of bolts used in oil and gas pipeline systems?The most commonly used bolts include stud bolts with heavy hex nuts, hex head bolts, and anchor bolts, particularly for flange connections, valve installations, and structural support.

Q2: Why is material selection important for pipeline bolts?Pipeline environments involve high pressure, extreme temperatures, and corrosive media like H₂S or saltwater. Material selection ensures the bolts can withstand these conditions without failure, enhancing safety and reliability.

Q3: What standards govern bolts for oil & gas pipeline applications?Key standards include ASTM A193 / A194 for high-pressure and high-temperature bolting, ASME B16.5/B16.47 for flanges, and NACE MR0175/ISO 15156 for sour gas corrosion resistance.

Q4: Are stainless steel bolts suitable for all oil and gas pipeline environments?Not necessarily. While stainless steel offers good corrosion resistance, environments with sour gas or extreme salinity often require more specialized materials like Inconel, Monel, or Super Duplex.

Q5: What types of coatings are applied to pipeline bolts to enhance corrosion resistance?Common protective coatings include PTFE (Teflon), Xylan, hot-dip galvanizing, and zinc plating, which enhance corrosion resistance and ease of installation.

Q6: How are bolt failures prevented in pipeline systems?By using the correct material grade, applying proper torque during installation, following maintenance schedules, and ensuring compliance with relevant engineering standards and certifications.

Q7: What is the role of stud bolts in pipeline flange assemblies?Stud bolts provide even clamping force across the flange face when used with heavy hex nuts, ensuring a leak-proof and secure connection in high-pressure pipeline systems.

Q8: Can coated bolts be used in subsea pipeline systems? Yes, but the coating and base material must be selected carefully. In subsea applications, corrosion-resistant alloys like Super Duplex or Inconel, often coated with PTFE or Xylan, are preferred for longevity and performance.

#OilAndGas#PipelineBolts#IndustrialFasteners#HighStrengthBolts#PipelineConstruction#StudBolts#ASMEBolts#ASTMA193#HeavyHexNuts#AnankaFasteners#BoltsAndNuts#OilAndGasEngineering#Ananka#Articles#Blog#tumblr blog#tumblr

0 notes

Text

Ped-Lock Valves – Leading Pressure Safety Valve Manufacturer in India

In high-pressure industrial systems, safety is paramount. A minor pressure surge can result in catastrophic equipment failure, personal injury, or environmental damage. That’s why choosing the right pressure safety valve (PSV) is not just about compliance—it's about protecting your people, your plant, and your profitability.

At Ped-Lock Valves & Fittings, we are proud to be a trusted pressure safety valve manufacturer in India, offering precision-engineered valves that deliver reliable overpressure protection in demanding industrial environments.

What Is a Pressure Safety Valve?

A pressure safety valve (PSV) or pressure relief valve (PRV) is a fail-safe mechanism designed to automatically release pressure from a system when it exceeds safe limits. Once the pressure drops back to a safe level, the valve reseats, ensuring system integrity and uninterrupted operation.

Key Features of Ped-Lock Pressure Relief Valves

Pressure Range: Up to 6000 PSI (414 bar) or customized per application

Material Options: SS 316, SS 304, Brass, Monel, and Hastelloy available

Connection Types: NPT, BSP, Tube OD, Compression, Socket Weld

Sizes Available: 1/4", 3/8", 1/2", 3/4", 1" and custom sizes

Set Pressure Adjustment: Spring-loaded mechanism for easy calibration

Leak-Proof Seal: With soft or metal-to-metal seating

Certifications: Designed and tested to API, ASME, and ISO standards

Applications of Pressure Relief Valves

Our pressure safety valves are suitable for:

Instrument air & gas systems

Hydraulic and pneumatic equipment

Chemical processing units

Oil & gas pipelines

Steam, water, and compressed air lines

Pump and compressor safety systems

They are critical to preventing pressure-related damage and ensuring compliance with industrial safety norms.

Why Ped-Lock Is a Preferred Pressure Safety Valve Supplier

30+ years of manufacturing excellence

CNC-machined components for accurate pressure control

100% tested for crack pressure, seat tightness, and backpressure performance

Widely used in Indian and global refineries, power plants, and OEM systems

In-stock options and custom-engineered solutions

Whether you're upgrading safety systems or specifying valves for a new build, Ped-Lock ensures precision, safety, and serviceability.

Get a Quote or Speak with a Valve Expert

Explore our range of pressure relief valves here: View Product Page

0 notes

Text

Unlock Specialized Power with Premium Specialty Caterpillar Tools

In the demanding world of heavy machinery and diesel engine maintenance, generic tools often fall short. Precision, power, and reliability are essential, especially when working on Caterpillar engines. That’s why professionals across the country turn to Tillman Tools, LLC—your trusted provider of high-performance Caterpillar Tools designed specifically for tough jobs. Our line of Specialty Caterpillar Tools is engineered to handle complex servicing tasks with unmatched accuracy and durability.

Purpose-Built Tools for Caterpillar Engines

Caterpillar engines power the world’s heaviest equipment—from bulldozers and excavators to haul trucks and generators. These engines are mechanical marvels, requiring meticulous care and precision when being serviced or rebuilt. Using off-the-shelf tools can lead to inaccurate results, engine damage, and unnecessary downtime.

At Tillman Tools, LLC, we specialize in premium CAT Service Tools that are designed with the exact dimensions, torque tolerances, and performance needs of Caterpillar engines. Whether you're working on a CAT 3406, C15, or 3126 engine, our tools deliver precision that generic equipment simply cannot match.

Our Extensive Range of Specialty Caterpillar Tools

Our inventory of Specialty Caterpillar Tools covers every major aspect of CAT engine service, from timing and calibration to fuel system repairs and cylinder head maintenance. Each tool is carefully selected, tested, and validated for professional-grade performance in real-world working environments.

Timing and Alignment Tools

Camshaft alignment tools

Crankshaft locking fixtures

TDC locators

Timing pin sets

These tools ensure accurate synchronization of engine components, preserving performance and avoiding catastrophic engine failure.

Fuel System Tools

Fuel injector sleeve pullers and installers

Common rail testing kits

Injector timing tools

Pressure testing adapters

Our fuel system tools ensure precise handling of CAT’s high-pressure fuel systems, which is critical to maintaining fuel efficiency and engine longevity.

Cylinder Head and Valve Tools

Valve spring compressors

Rocker arm setting tools

Cylinder head lifting fixtures

Valve guide reamers

These tools make valve service and head repairs faster, safer, and more accurate, saving valuable labor time and reducing the margin for error.

The Tillman Tools Advantage

When you choose Tillman Tools, LLC, you're not just buying CAT Service Tools—you’re investing in tools engineered to outperform, outlast, and deliver measurable value over time. Our products are built from high-grade alloy steel and precision-machined to exact tolerances. They are rigorously tested to meet the needs of heavy-duty CAT repair applications, ensuring:

High durability in tough conditions

Perfect fitment for CAT engine components

Improved efficiency and reduced repair time

OEM compatibility across multiple engine models

With our tools, every mechanic and technician gains the confidence to tackle any CAT engine challenge.

Serving All Caterpillar Engine Platforms

We offer tools compatible with a broad spectrum of Caterpillar engines, including:

CAT 3116, 3126

CAT C7, C9, C12, C13, C15, C18

CAT 3406, 3456

Marine, on-road, and off-road equipment

From industrial power units to heavy construction machinery, our Caterpillar Tools are designed to support both legacy and current-generation CAT engines.

Trusted by Professionals Nationwide

Our clients include independent mechanics, large repair facilities, fleet maintenance managers, and dealership technicians who demand precision and dependability in every tool. Their trust in Tillman Tools, LLC is built on our unwavering commitment to excellence, responsive customer service, and consistently high-quality products.

We understand that downtime costs money. That’s why we offer:

Fast and reliable shipping

Expert support and consultation

Easy-to-navigate online ordering

Competitive pricing on all tools

Upgrade Your Workshop with Tillman Tools

Investing in our Specialty Caterpillar Tools means equipping your workshop with the precision and power needed to handle any CAT repair task with confidence. Say goodbye to improvising with substandard tools and elevate your repair standards with products that professionals trust.

Visit our online store at Tillman Tools, LLC to browse our complete selection of premium CAT Service Tools and discover the difference real quality makes.

0 notes

Text

The Unseen Workhorse: How Compressor Felt Drives Efficiency and Longevity

In the industrial world, air and gas compressors are indispensable machines, powering everything from manufacturing lines and pneumatic tools to refrigeration systems and medical equipment. They are the lungs of many operations, converting power into compressed air or gas. But lurking within these robust machines, often unnoticed, is a critical component that ensures their smooth, efficient, and long-lasting operation: Compressor Felt.

Far from being a mere piece of fabric, compressor felt is a highly engineered nonwoven material, specifically designed to perform vital functions such as filtration, sealing, sound dampening, and absorption. Its quality directly impacts the performance, lifespan, and maintenance costs of your valuable compressor systems.

At PARKNONWOVEN, with our state-of-the-art manufacturing facilities in Gurugram, Haryana, India, we are a leading producer of high-quality nonwoven felts, precisely engineered to meet the demanding requirements of various compressor applications.

The Unsung Workhorse: What is Compressor Felt?

Compressor felt refers to specialized nonwoven felt materials that are integrated into various parts of air and gas compressors. Unlike woven fabrics, felt is produced by mechanically or thermally interlocking fibers into a dense, matted structure. This unique construction provides specific properties essential for compressor functionality.

These felts are not a one-size-fits-all solution; they are meticulously designed based on their intended role within the compressor system, serving as:

Filtration Media: Capturing airborne particulates, oil mist, or moisture.

Sealing Elements: Creating tight seals between components to prevent leaks.

Acoustic Dampeners: Absorbing noise and vibration.

Absorption Pads: Wicking or holding lubricants, or absorbing contaminants.

Beyond the Machine: Why Compressor Felt is Indispensable for Performance

The precise function of compressor felt is critical for several reasons:

Protecting Internal Components: High-quality filtration felt prevents abrasive particles from entering and damaging sensitive moving parts like pistons, rotors, and valves.

Ensuring Clean Air/Gas Output: For applications requiring pure, uncontaminated air (e.g., medical, food processing, electronics manufacturing), the felt filter ensures that the output is free from dust, oil mist, and other impurities.

Noise Reduction: Compressors can be noisy machines. Felt materials serve as effective acoustic insulation, dampening vibrations and reducing operational noise levels, contributing to a better working environment.

Enhancing Efficiency & Longevity: Proper filtration reduces wear and tear, leading to less friction, lower energy consumption, and significantly extending the overall service life of the compressor.

Preventing Leaks: As gasket material, felt provides a reliable seal under various pressures and temperatures, preventing expensive air or gas loss and maintaining system integrity.

Engineered for Demanding Environments: Key Properties of Effective Compressor Felt

The performance requirements for compressor felt are rigorous, demanding specific material properties:

High Filtration Efficiency: The ability to consistently capture a wide range of particle sizes without excessive pressure drop.

Oil/Moisture Absorption & Retention: For oil mist separation or lubrication wicking, the felt must effectively absorb and hold liquids without degradation.

Excellent Acoustic Dampening: A porous, dense structure that can effectively absorb sound waves and vibrations.

Superior Sealing & Gasketing: The ability to conform to surfaces, withstand compression, and maintain a tight seal under varying temperatures and pressures.

Temperature Resistance: Capable of operating consistently within the compressor's specific temperature range, from ambient intake air to high-temperature compressed gas.

Chemical Compatibility: Resistance to various compressor oils, refrigerants, and atmospheric contaminants encountered during operation.

Durability & Resilience: Withstanding continuous mechanical stress, compression, and airflow without degradation, tearing, or shedding fibers.

Consistent Thickness & Density: Uniformity across the material ensures predictable and reliable performance in critical applications.

The Fabric of Functionality: Materials and Types of Compressor Felt

The choice of fibers and the manufacturing process are crucial for tailoring compressor felt to its specific role. Common materials used include:

Polyester (PET) Felt: A versatile and widely used synthetic fiber known for its strength, durability, good temperature resistance, and chemical compatibility with many compressor oils. It's often needlepunched to achieve desired density and porosity for filtration and dampening.

Polypropylene (PP) Felt: Offers excellent chemical resistance, especially to acids and alkalis, and is often used where moisture absorption is critical or for lower temperature applications.

Blends and Specialty Fibers: For highly specific requirements, blends of synthetic fibers or even natural fibers like wool (known for excellent oil absorption and acoustic properties in certain traditional applications) might be considered, though modern compressors heavily favor engineered synthetics.

The needlepunching process is particularly effective for creating compressor felts, as it allows for precise control over the felt's density, thickness, and porosity, enabling customization for specific filtration or acoustic dampening performance.

Where Felt Makes a Difference: Key Applications within Compressors

Compressor felt finds diverse applications within various types of compressors:

Air Intake Filters: Essential for capturing dust, dirt, and other airborne particulates before they enter the compressor's delicate internal mechanisms.

Oil Separator Elements: In oil-lubricated compressors, felt layers are crucial for separating oil mist from the compressed air/gas stream, ensuring cleaner output.

Gaskets and Seals: Used around flanges, covers, and other mating surfaces to prevent air/gas leaks and maintain system pressure.

Acoustic Insulation & Liners: Applied within compressor enclosures or around noisy components to absorb sound and reduce operational noise levels.

Vibration Dampening Pads: Placed under mounting points or between vibrating components to absorb mechanical vibrations and prevent their transmission.

Lubrication Wicks: In some smaller compressors, felt can be used to wick and distribute lubricants to bearing surfaces.

The Hidden Benefits: Investing in High-Quality Compressor Felt

Choosing the right, high-quality compressor felt offers a cascade of advantages:

Improved Air/Gas Purity: Ensures the compressed medium meets stringent quality standards for various industrial and sensitive applications.

Extended Compressor Lifespan: Reduces wear and tear on expensive internal components, delaying costly repairs and replacements.

Reduced Maintenance Costs: Fewer breakdowns, less frequent filter changes, and longer component life lead to significant savings.

Quieter Operation: Creates a more comfortable and compliant working environment by effectively dampening noise.

Enhanced Energy Efficiency: Clean components and proper sealing mean the compressor doesn't have to work harder than necessary, leading to lower energy consumption.

PARKNONWOVEN: Precision-Engineered Nonwoven Felts for Compressor Excellence

At PARKNONWOVEN, we understand that the performance of your compressor systems hinges on the quality of every component, no matter how small. As a leading manufacturer of high-quality nonwoven felts in Gurugram, Haryana, India, we are uniquely equipped to meet the precise demands of compressor applications.

Our capabilities in compressor felt manufacturing include:

Customized Material Solutions: We produce nonwoven felts from a variety of synthetic fibers (e.g., polyester, polypropylene) in various densities, thicknesses, and GSMs (Grams per Square Meter) to match specific filtration, sealing, or acoustic requirements.

Engineered Performance: Our felts are designed with controlled porosity, compressibility, and resilience to ensure optimal airflow, effective sealing, and superior acoustic dampening under operational conditions.

Robust Durability & Compatibility: We ensure our felts exhibit excellent resistance to oils, chemicals, and temperature fluctuations, providing long-lasting performance in demanding compressor environments.

Consistent Quality: Through stringent manufacturing processes and quality control, we guarantee uniform felt products that deliver reliable and predictable performance.

By partnering with PARKNONWOVEN, you secure a foundation of excellence for your compressor systems, ensuring cleaner air, longer lifespan, and more efficient operation.

Conclusion: Small Component, Big Impact

Compressor felt may be a relatively small and often overlooked component, but its role in the efficiency, longevity, and safety of air and gas compressors is undeniable. Investing in high-quality, engineered compressor felt is a proactive step towards optimizing your industrial operations, reducing costs, and ensuring reliable performance.

Optimize Your Compressor Performance. Partner with PARKNONWOVEN for Advanced Nonwoven Felt Solutions!

Don't let subpar components compromise your valuable compressor systems. For robust filtration, reliable sealing, and effective noise reduction, the right compressor felt makes all the difference. PARKNONWOVEN is your trusted expert in manufacturing precision-engineered nonwoven felts tailored for the demanding world of compressors.

Choose the expertise, cutting-edge technology, and unwavering quality that define PARKNONWOVEN.

Contact our dedicated team of nonwoven specialists NOW! Let's discuss your specific compressor felt requirements and explore how our advanced nonwoven solutions can enhance the efficiency, longevity, and operational excellence of your compressed air and gas systems. Your path to superior performance starts here, in Gurugram, Haryana.

#CompressorFelt#NonwovenFelt#FiltrationMedia#IndustrialMachinery#PARKNONWOVEN#AirCompressor#GasCompressor#IndustrialFelt

0 notes

Text

Beat the Oklahoma Heat with Expert Air Conditioner Repair in OKC by Covington Heat and Air LLC

youtube

When the scorching Oklahoma summer rolls in, having a dependable air conditioning system is essential—not a luxury. As temperatures soar across Oklahoma City, a breakdown in your cooling system can turn your living space into an unbearable environment. That’s why prompt, professional air conditioner repair is critical, and Covington Heat and Air LLC is the local company homeowners and small businesses trust to get the job done right.

With years of hands-on experience and a solid reputation in Edmond and the greater OKC metro area, Covington Heat and Air LLC provides fast, reliable AC repair services that restore your comfort quickly. If your air conditioner is acting up, this locally owned company is ready to respond with fair pricing, quality workmanship, and exceptional customer care.

The Importance of Reliable AC Repair in OKC In Oklahoma City, summer temperatures frequently reach the upper 90s, with triple digits not uncommon. These extreme conditions can take a toll on HVAC systems, often causing unexpected failures. A broken AC system during these peak temperatures isn’t just an inconvenience—it’s a potential health hazard, especially for children, the elderly, and individuals with underlying health conditions.

That’s why Covington Heat and Air prioritizes quick response times and same-day service when possible. Your comfort and safety are their top priorities, and their technicians are trained to diagnose and fix issues fast—often on the first visit.

Signs Your Air Conditioner May Need Repair It’s not always easy to tell when an air conditioner is on the verge of failing. Recognizing early warning signs can help you avoid complete system breakdowns and costly emergency repairs. If you notice any of the following issues, it may be time to schedule a service call with Covington Heat and Air:

Insufficient Cooling: If your AC is blowing warm air, even when set to a low temperature, it could be due to low refrigerant, compressor problems, or a failing thermostat.

Low Airflow: Weak airflow may result from dirty filters, ductwork issues, or blower motor failure.

Loud or Strange Noises: Banging, buzzing, or screeching sounds coming from your system should not be ignored. These noises often signal loose components or mechanical damage.

Unpleasant Odors: Musty or burnt smells might point to mold buildup or electrical issues within the system.

Increased Energy Bills: A spike in your utility costs without a change in usage can be a sign that your AC is running inefficiently.

Frequent On-Off Cycling: If your unit is cycling more frequently than normal, it may be struggling to maintain the desired temperature.

Acting quickly when you spot these signs can help extend the life of your AC unit and avoid more extensive damage.

Local Professionals with a Personal Touch Covington Heat and Air LLC has been serving Oklahoma since 2007, offering personalized HVAC solutions with a focus on quality and trust. Unlike large national chains, this family-owned business treats each customer like a neighbor, providing honest advice and dependable service tailored to your specific needs.

Their team of licensed HVAC technicians has experience with a wide range of brands and models, including both modern energy-efficient systems and older units. Whether it’s a residential home or a small commercial property, Covington Heat and Air is fully equipped to tackle any cooling problem you may have.

What Makes Covington Heat and Air Stand Out? With so many HVAC contractors in Oklahoma City, it can be hard to choose the right one. Here’s why Covington Heat and Air is a standout choice:

Fast, Reliable Response: You won’t be left waiting days for service. Covington’s team strives to provide timely repairs, especially during emergencies.

Transparent Pricing: You’ll receive clear quotes before any work begins, with no hidden fees or pressure sales tactics.

High-Quality Repairs: Their technicians deliver long-lasting solutions, not quick patches that lead to recurring problems.

Friendly Service: Customers consistently praise the company for its professionalism, courtesy, and commitment to satisfaction.

Community-Oriented: Being locally owned means they care about the people they serve. Their reputation depends on your satisfaction.

Full-Service HVAC Solutions In addition to air conditioner repair in OKC, Covington Heat and Air LLC offers a full suite of HVAC services to keep your home comfortable year-round:

New System Installations: Whether building a home or upgrading to a more efficient system, their installation services make the process hassle-free.

Heating Repairs: When winter arrives, they’re just as prepared to handle furnace or heat pump issues.

Preventive Maintenance: Regular inspections and tune-ups help extend the life of your system, improve efficiency, and reduce the risk of costly repairs.

Their maintenance plans are a smart investment, offering peace of mind and consistent performance throughout Oklahoma’s extreme weather seasons.

Proudly Serving Oklahoma City and Beyond From Edmond to Norman and everywhere in between, Covington Heat and Air is committed to providing dependable HVAC services across the OKC metro area. They understand the local climate and the specific challenges it poses for air conditioning systems—and they’re always just a call away when your system needs expert attention.

Don’t Sweat It—Call Today When your air conditioner breaks down, you need more than just a quick fix—you need a team you can trust. With Covington Heat and Air LLC, you get experienced professionals, responsive service, and honest pricing every time.

Don’t let summer heat take over your home. Schedule your air conditioner repair in OKC with Covington Heat and Air today. Call or visit their website to book an appointment and restore comfort and peace of mind to your home or business.

0 notes

Text

ROTARY SCREW AIR COMPRESSORS

ELGi’s rotary screw air compressors are the backbone of African industries, offering high energy efficiency, advanced features, and cost-effective performance. The EN and EG series support applications ranging from light to heavy-duty in manufacturing, food processing, pharmaceuticals, mining, and construction, ensuring low operating costs, reduced downtime, and increased productivity through ELGi’s extensive network of channel partners.

HOME

PRODUCTS

ROTARY SCREW AIR COMPRESSORS

Screw compressorspiston compressors

ELECTRIC LUBRICATED SCREW AIR COMPRESSOR

EN SERIES SCREW AIR COMPRESSORS 2.2–15 KW

ELGi’s EN series screw air compressors are known for their reliability, low maintenance requirements and small footprint, which make them ideal for industrial applications where size, efficiency and cost matter.

ELECTRIC LUBRICATED SCREW AIR COMPRESSORS

EQ SERIES SCREW AIR COMPRESSORS 11–45 kW

The ELGi EQ Series offers unmatched reliability, built tough for a long-lasting performance. Backed by a best-in-class warranty and requiring minimal maintenance, it stands out as a reliable air compressor for industries where size, reliability, and cost are paramount. These air compressors excel in the most demanding and challenging conditions, providing maximum uptime and extended life. Designed for customer-specific applications, the ELGi EQ Series sets the standard for excellence in compressed air maintenance, delivering exceptional value for small and medium enterprises (SMEs). When you need a reliable compressor that won’t break the bank, the EQ Series is your ideal choice.

KNOW MORECONNECT WITH US

ELECTRIC LUBRICATED SCREW COMPRESSORS

EG SERIES SCREW COMPRESSOR

WHAT IS A ROTARY SCREW AIR COMPRESSOR AND WHAT ARE ITS BENEFITS?

A rotary screw air compressor is, simply, rotary positive displacement air compressor, capable of high-speed operation over a wide range of operating pressures and flow rates while offering high efficiency. In screw air compressors, there are no valves or other mechanical forces that can cause obstruction during the compression process. This allows a compressor to operate at high speeds while combining a large flow rate while still being compact than other technologies. The main advantage of using a rotary screw air compressor is that it supplies compressed air continuously with minimal fluctuation in delivery pressure and optimises thermal energy management.

Industrial rotary screw air compressors are instrumental in enhancing productivity, efficiency, and operational cost across various industries by delivering reliable and consistent compressed air for a wide range of applications.

Other advantages of using rotary screw air compressors that will help Africa’s industries grow, include:

Convenient, as they deliver air continuously for the required purposes, and safe, as the chances of having an accident are minimal.

Functions at extreme weather conditions as the compressor can work at high temperatures or in low conditions to suit your convenience and at any forms of energy or temperatures levels.

Lowers maintenance costs drastically.

Long-lasting, as they have little or no capacity reduction.

Designed to run tools that generate more power than typical equipment.

Low noise output machine.

Minimum oil-carryovers, as low as 3 ppm in oil lubricated machine.

ELGi’S ROTARY SCREW AIR COMPRESSOR PROFILE

ELGi screw type compressor profile consists of several segments, each with a different shape.

Large positive displacement which increases the pressure by reducing its volume.

Strong female rotor which helps in more tapping of air and reduction of space continuously.

Short sealing line that maintains a seal over the entire contact length which eliminates the need for a sealing strip.

Better clearance distribution.

WHAT IS THE WORKING PRINCIPLE OF ROTARY SCREW AIR COMPRESSOR?

The Rotary Screw air compressor uses a rotary-type positive-displacement mechanism. The screw element consists of two rotors that are similar to a helix, each with a different shape and number of grooves/teeth. Atmospheric air is sucked into this screw element, and as the air progresses along the two interlocking rotors, it gets compressed. The main characteristic of this type of compressor is a male and a female rotor element, which traps the air and compresses it as it passes across the airend.

In an oil-lubricated rotary air compressor, the male rotor is driven by the electric motor or engine, which in turn drives the female rotor and compresses the air due to a reduction in volume.

In an oil-free rotary air compressor the lubricating media is a special coating on the rotors instead of oil which ensures 0 oil carryover to the outlet.

The basic principle of a rotary-type compressor is that both the male and female rotors are spinning in opposite directions. The prime mover turns the rotor of the airend in a rotary screw air compressor. This creates a vacuum resulting in surrounding air being driven into the airends through the air filter. As the rotors turn progressively, the air gets trapped in the spaces between the two screws (rotors).

Air is taken from the atmosphere into the rotary screw compressor through the air intake system. It passes through a filter that helps in removing suspended particles from it. The filtered air goes in the airend, is the heart of the screw type compressor. Here, the air is trapped within the spaces between the two rotors with mesh lobes. . As the rotors turn, they progressively compress the trapped pockets of the air, and the compressed air is discharged at the outlet of the airend.

ELGi’s EN & EG series, rotary screw electric air compressors offer best-in-class performance and are engineered for easy maintenance and operation for industries in Africa.

Rotary Screw Air Compressors- A Boon to Diverse Industries

Investing in a Rotary Screw Air Compressor ensures a continuous and reliable compressed air supply. In today’s dynamic business world, these air compressors are indispensable tools for optimising manufacturing processes and achieving peak production performance. The electric powered rotary screw air compressors are suitable for a wide range of pneumatic applications. Additionally, a variable frequency drive can significantly improve the energy savings for screw air compressors when deployed for the right duty cycle.

The rotary screw compressor provides reliable compressed air for various industrial applications in Africa.

Manufacturing Industry

Rotary Screw Compressors are well-suited for manufacturing applications due to their ability to deliver a constant airflow and maintain consistent pressure levels. Air compressors are essential for powering pneumatic tools, air-operated machinery, and production lines.

Automotive Industry

The automotive industry extensively uses compressed air for various applications, including assembly line tools, paint booths, and pneumatic controls. Additionally, the compact design of these compressors is beneficial for automotive workshops with limited space.

Food and Beverage Industry

The food and beverage industry often requires compressed air for packaging, bottling, and pneumatic conveying systems. In such sensitive environments, oil-free rotary screw compressors are preferred to prevent any risk of oil contamination. These compressors provide clean, high-quality compressed air, ensuring product safety and compliance with industry regulations.

Pharmaceutical Industry

In pharmaceutical manufacturing, where hygiene and air quality are critical, oil-free rotary screw compressors are essential to avoid any risk of oil contamination. These compressors provide a reliable source of contaminant-free compressed air, crucial for various processes like pharmaceutical product packaging, filling, and sealing.

Textile Industry

The textile industry utilises compressed air for spinning, weaving, dyeing, and finishing processes. Rotary air compressor offers consistent and reliable air supply to power pneumatic tools and machines, improving productivity and efficiency in textile manufacturing operations.

Rotary Screw Air Compressors for Sale

Explore our range of screw air compressors engineered to meet your industrial needs with superior performance, energy efficiency, and long-lasting reliability.

0 notes